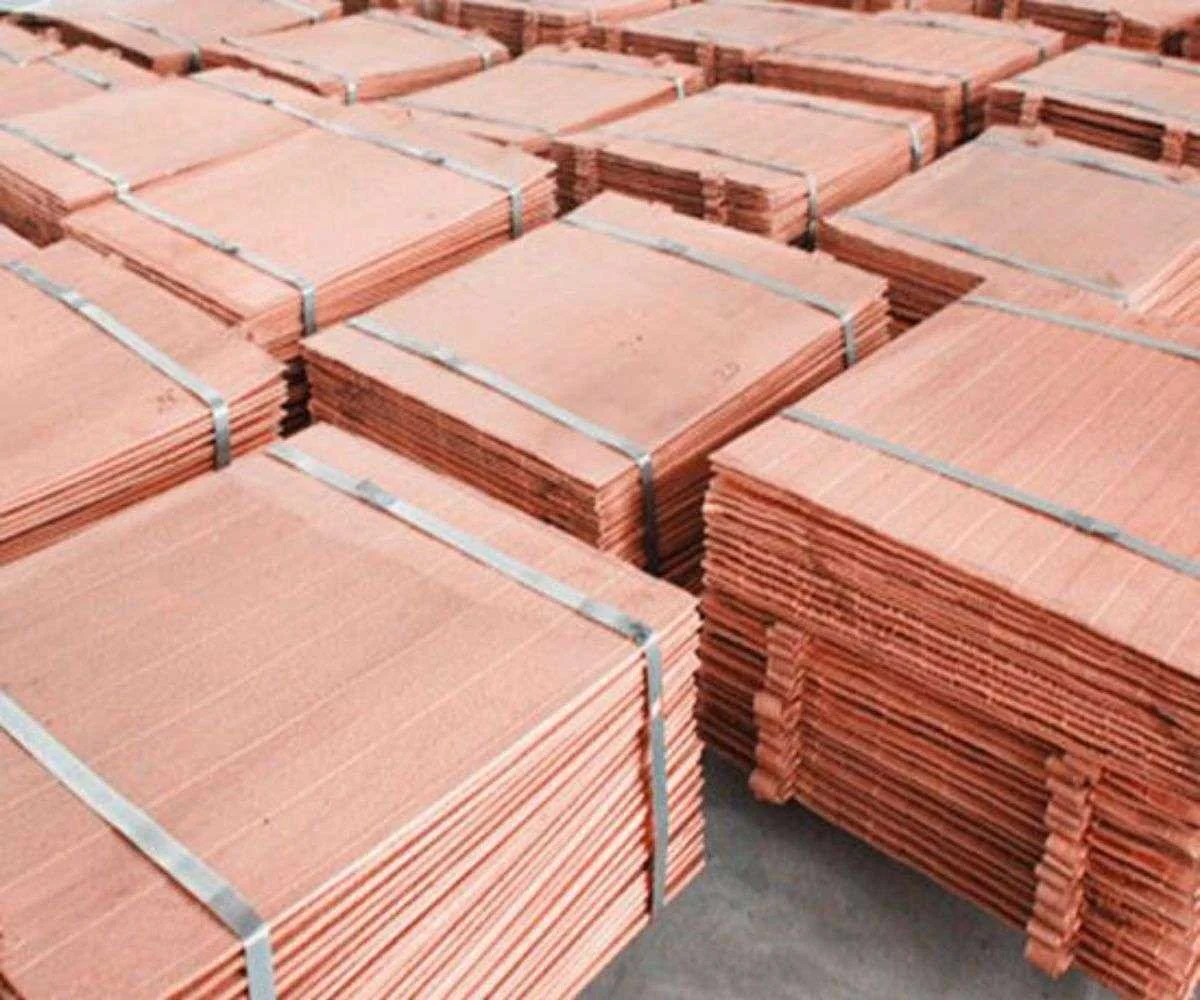

Copper Cathodes

Main uses of copper cathodes by our customers :

-

Power cables & high-voltage lines

Printed circuit boards (PCBs)

Transformers & Switchgear

Electric motors and Generators

Batteries and charging systems (EVs)

-

Wiring harnesses in vehicles

Conductive components in EVs

Radiators and brake tubing

Batteries and charging systems (EVs)

-

Alloy production (brass, bronze)

Semiconductors and connectors

Precision components and industrial tooling

-

Plumbing systems (pipes, fittings)

Roofing and architectural elements

Grounding systems for buildings

HVAC systems (heating/cooling)

-

Grade A Electrolytic Copper

Purity : 99.99%

-

BS EN 1978:1998 (CU-CATH-1 Cathodic Quality Indication)

-

Africa

-

Human Rights and Labor Standards : Zero tolerance for child labor and forced labor

Local Impact and Transparency : Fair compensation to local communities and workers

The main advantages of copper cathodes in industry. Why Copper Cathodes Matter :

High Conductivity : Best-in-class electrical performance

Corrosion Resistance : Ideal for long-term infrastructure

Recyclability : 100% recyclable with no loss in quality

Versatility : Compatible with casting, rolling, extrusion, etc.

⚡ Superior Electrical Conductivity

High-purity copper (≥ 99.99%) ensures maximum conductivity, making it essential for applications such as electrical wiring, motors, transformers, and EV batteries. Even small impurities can significantly increase electrical resistance, causing energy losses and overheating.

🔩 Improved Mechanical Performance

Impurities weaken the copper’s structure. Pure cathodes provide better ductility and strength, allowing easier drawing, rolling, and forming during manufacturing processes — critical for cable producers, sheet metal processors, and industrial parts suppliers.

🧪 Consistency & Compliance

With LME Grade A certified cathodes (≥ 99.99%), you meet the standards required by international buyers, regulators, and manufacturers. Consistency in purity ensures reliable downstream processes, better welding, and fewer product defects.

🛡 Enhanced Corrosion Resistance

Purity also means better long-term durability. Low levels of contaminants reduce the risk of corrosion, oxidation, and structural failure — a must-have for plumbing, roofing, and power transmission infrastructure.

Responsible Mining, Ethical Commitment

At Hydolys Group, we believe that economic performance must go hand-in-hand with social and environmental responsibility. That’s why all our copper cathodes are sourced from verified mining operations in Africa that strictly adhere to :

🌱 Human Rights and Labor Standards

-Zero tolerance for child labor and forced labor.

-Compliance with ILO conventions and national labor laws.

-Fair working conditions and safety protocols for all workers.

-Regular audits by independent third-party organizations.

🌍 Environmental Responsibility

-Implementation of clean extraction and refining techniques to minimize water and soil pollution.

-Waste and emissions control systems in line with international norms.

-Programs for land rehabilitation and biodiversity protection around mining sites.

🤝 Local Impact and Transparency

-Fair compensation to local communities and workers.

-Support of local employment and training programs.

-Transparent and traceable supply chains, with full documentation.